Products

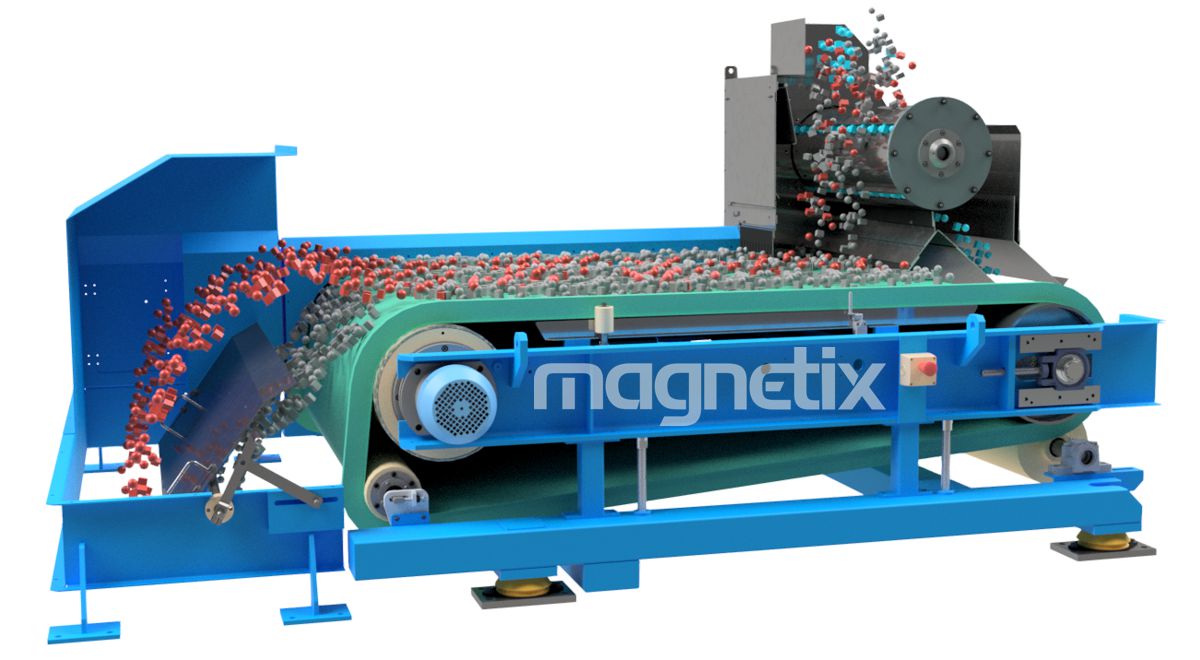

Eddy current separator SWP

The SWP type eddy current separator equipped with a drum separator is designed for automatic separation of ferrous and non-ferrous metals from bulk or crushed materials. The SWP separator recovers ferrous metals and valuable non-ferrous metals such as aluminium, copper, magnesium, zinc and silver with high efficiency. In addition, the separator cleans secondary raw materials such as plastics and glass from ferrous and non-ferrous metals.

The SWP non-ferrous metal separator is reliable, very robust and designed for continuous operation. The separator is characterized by high metal separation efficiency. The powerful neodymium permanent magnets used in the polar wheel have high coercivity, which makes them difficult to demagnetize. Therefore, the SWP separator has a long service life.

Features of eddy current separators from Magnetix

- Custom made eddy current separator according to individual requirements.

- Robust and durable design for continuous operation 24/7 under difficult working conditions.

- Working width of the eddy current separator up to 2000 mm.

- High-speed eddy current rotor (polar wheel) made of powerful neodymium magnets.

- Speed of the polar wheel up to 4500 RPM due to innovative bearing cooling.

- The frequency of the alternating magnetic field up to 1200 Hz.

- Precise balancing of the polar wheel in class 0.4

- Adjustment of operation parameters with frequency inverters.

- The latest security systems, including electronic rotor braking.

- Reinforced C-type frame enabling quick belt replacement (belt replacement time approx. 30 minutes).

- Corrugated sidewall conveyor belt with increased durability.

- Accessories from leading manufacturers.

Applications of non-ferrous metal separators

- Recovery of non-ferrous metals from municipal and industrial waste.

- Separation of non-ferrous metals from alternative fuels RDF.

- Valorization of slags from municipal waste incineration plants.

- Disposal of cars and household appliances

- Recycling of electronic waste (E-waste).

- Plastic recycling.

- Purification of glass cullet.

- Recovery of metals from mining and processing heaps.

- Purification of wood chips.

Eddy current separation of non-ferrous metals

- aluminum

- copper

- brass

- magnesium

- zinc

- tin

- silver

- gold

- lead

Versions of eddy current separators

- Aluminum can separator type SWP-12B

Equipped with a 12-pole magnetic rotor for metal separation > 50 mm. - Eddy current separator type SWP-18B

Equipped with an 18-pole magnetic rotor designed for separating metals from 10 to 50 mm. - Eddy current separator type SWP-26B

Equipped with a 26-pole magnetic rotor designed for separating metals from 1 to 10 mm.

Separator accessories

- Discharge hood with an adjustable splitter.

- Drum separator for separating ferrous metals.

- Rotating brush for belt cleaning.

- Belt alignment switches and rotation sensor.

- Control cabinet equipped with SIEMENS PLC.

- Frequency inverters for rotor and belt speed adjustment.

Working principle of the eddy current separator

The operation of the eddy current separator is based on the principle of magnetic induction. A magnetic rotor rotating at high speed creates a high frequency alternating magnetic field that induces strong eddy currents in metals. Due to the flow of current in non-ferrous metals, a secondary magnetic field is created that opposes the magnetic field of the rotor. The interaction of these fields leads to the creation of the Lorentz repulsive force, which counteracts the force of gravity. The resultant force pushes the metal out of the stream of transported material. The SWP-26B separator is characterized by a high-frequency magnetic field ensuring the highest separation efficiency of very fine metals such as aluminium, copper, magnesium, zinc and silver.

Eddy current separator videos

Why choose our eddy current separators?

Eddy current separators from Magnetix are proven solutions manufactured for over 25 years for customers throughout Europe. The devices are manufactured entirely in Poland, in a modern production plant located in the Toruń Technology Park. The highest quality materials and components of our own production used in the separators guarantee high efficiency and reliability.

SWP separators are available in many variants, adapted to the efficiency, type of waste, granulation and local operating conditions. Magnetix devices are each time selected for the type of raw material and the type of metals that need to be separated in order to obtain the highest possible efficiency and effectiveness of metal recovery. The customer receives a tailor-made device, thanks to which he can achieve high metal separation efficiency, and thus the expected economic effect and quick return on investment.

Eddy current separators are powered and controlled via a control cabinet developed and manufactured by Magnetix. Modern drive systems, power supply and control systems consume up to 30% less electricity compared to competitive solutions, which has measurable benefits in the annual energy balance. The separator has a special C-type frame, enabling very quick replacement of the conveyor belt and other separator components, which is very important in plants with continuous operation, where longer downtime is unacceptable.

Producer – Magnetix Sp. z o. o. guarantees efficient and fast warranty and post-warranty service throughout Europe and the availability of all spare and consumable parts for a minimum period of 10 years of operation.

Eddy current separator price and delivery date

Based on the operating parameters specified by the Customer, the appropriate type of separator is selected and its price is determined, which depends primarily on the magnetic rotor installed in it. Depending on the material granulation and the size of metal impurities, 12-, 18-, 26- and even 36-pole rotors are offered. The most expensive are machines with a rotational speed of 4000 rpm. As standard, separators are supplied with NORD drives. The use of SEW drives requires a small additional fee. The color scheme of the device is optional - according to the RAL palette and does not require an additional fee.

The delivery date of the device on request is standardly 8 - 12 weeks. We also fulfill orders with an accelerated deadline. Magnetix also has a large warehouse of separators available immediately.

Magnetix also carries out comprehensive deliveries of eddy current separators including the design of the installation, steel structures, control systems and mechanical and electrical assembly. The price of a comprehensive separator delivery with assembly is calculated individually and depends on the complexity of the installation and the scope of work.