Products

Stainless steel separator SNS

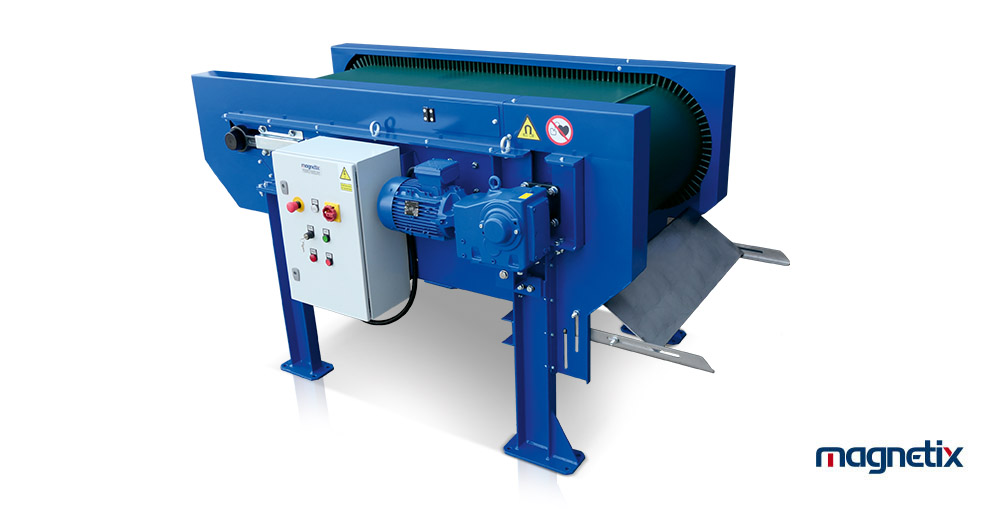

The SNS type stainless steel separator is designed for automatic separation of alloy steels from bulk or crushed materials.

The SNS separator is reliable, very robust and suitable for continuous operation. It is characterized by the highest separation efficiency of stainless steel. The powerful neodymium magnets used in the high intensity magnetic pulley have high coercivity, making them difficult to demagnetize. Therefore, the SNS separator has a long service life.

Features of stainless steel separators from Magnetix

- Custom made stainless steel separator according to individual requirements.

- Robust and durable design for continuous operation 24/7 under difficult working conditions.

- Working width of the separator up to 2000 mm.

- High intensity magnetic pulley made of powerful neodymium magnets.

- Adjustment of operation parameters with frequency inverters.

- Corrugated sidewall conveyor belt with increased durability.

- Accessories from leading manufacturers.

Applications of SNS separators

- Recycling of electronic waste (E-waste).

- Separation of alloy steel in the plastic recycling process.

- Disposal of cars and household appliances.

- Removing stainless steel from glass cullet.

Versions of stainless steel sorters

- SNS 15 type separator

Equipped with a 150 mm diameter high intensity magnetic pulley for separating metals < 10 mm. - SNS 25 type separator

Equipped with a 250 mm diameter high intensity magnetic pulley for separating metals from 10 to 50 mm. - SNS 40 type separator

Equipped with a 400 mm diameter high intensity magnetic pulley for separating metals > 50 mm.

Working principle of the stainless steel separator

The material to be separated is fed to the separator's conveyor belt continuously and evenly using a vibrating feeder. The belt conveyor is equipped with a high intensity magnetic pulley that generates a very strong magnetic field. Weakly magnetic pieces of stainless steel are captured by the magnetic field and held on the conveyor belt, while the magnetically neutral material falls freely from the conveyor. Pieces of stainless steel fall off the belt at the point where the belt no longer adheres to the pulley, either under the influence of gravity or with the help of cleats located on the belt. The operation of the separator is additionally supported by an adjustable splitter located under the pulley.

Why does stainless steel become magnetic?

Some stainless steel alloys are weakly magnetic or become weakly magnetic for a short period of time as a result of changes in the microstructure of the steel resulting from grinding of the material. This happens due to the transformation of the austenitic phase into martensite, which is ferromagnetic. This phenomenon depends largely on the chemical composition of the steel, in particular on the share of elements stabilizing the austenitic phase. Rust appears on bent and frayed pieces of alloy steel, indicating a change in the microstructure of the steel. In this way, the pieces of stainless steel become weakly magnetic and can be attracted to the very strong field generated by the high intensity magnetic pulley.

Why choose our stainless steel separators?

Stainless steel separators manufactured by Magnetix are available in several versions and are equipped with high-induction magnetic systems made of neodymium magnets. Separators are available in diameters up to 500 mm and working widths up to 2000 mm, adapted to the efficiency and installation conditions. An innovative technology of water jet cutting of magnets and yokes has been developed for the production of magnetic systems installed in separators, thanks to which very high precision of magnet assembly has been achieved, and consequently high power of the emitted magnetic field. The device design has many advantages: high magnetic field strengths, high resistance to abrasion, robust design, large grain size range (1 mm – 150 mm), high throughputs, minimal maintenance, good optimization options through a wide range of setting options and modular design.