Products

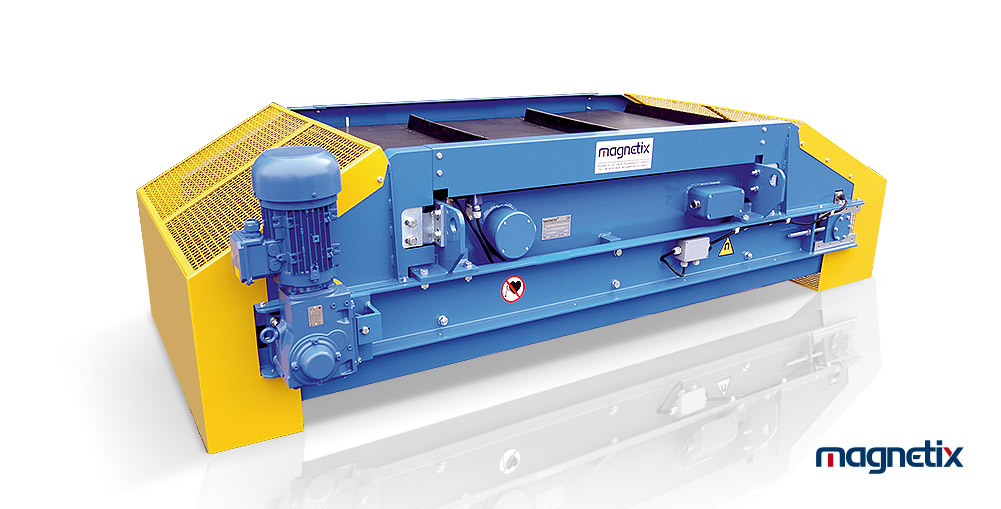

Electromagnetic separator STE

The STE type electromagnetic separator is designed for automatic separation of ferrous metals from bulk materials transported on belt conveyors or vibrating feeders. The Electro Magnetic Separator protects mills, crushers and other process machines against damage caused by iron parts such as screws, pipe pieces, bearings or crusher teeth. The STE separator is also used to recover valuable ferrous scrap in waste recycling processes.

The STE overband separator is reliable, very robust and designed for continuous operation. The separator is characterized by high metal separation efficiency. The electromagnet used in the separator has a high-quality winding made of aluminum tape with the highest class of insulation. This makes it resistant to high temperatures, very durable and efficient.

Features of electromagnetic separators from Magnetix

- Custom made Electro Magnetic Separator according to individual requirements.

- Optimal adaptation to the width and speed of the conveyor belt.

- Robust and durable design for continuous operation 24/7 under difficult working conditions.

- DC electromagnet with a power of up to 28 kW in continuous operation and 50 kW in intermittent operation.

- Magnetic circuit with deep magnetic field and high flux density.

- Magnetic field range up to 900 mm in accordance with DIN VDE 0580.

- High-quality electromagnet winding made of aluminum tape.

- Electromagnet insulation made in class C up to 300°C.

- IP 65 protection degree of the electromagnet.

- Reinforced rubber belt with hot vulcanized cleats.

- Belt drive - NORD or SEW helical-bevel gear motor. Other manufacturer on request.

- Accessories from leading manufacturers.

- Optional explosion-proof design in accordance with the requirements of the ATEX directive.

Applications of overband electromagnets

- Separation of tramp metal from coal, granite, limestone, basalt and other aggregates to protect mills and crushers.

- Removal of metal contaminants at particular stages of cement production.

- Recovery of iron scrap from mining and processing heaps.

- Separation of tramp iron from moulding sand.

- Recovery of ferrous scrap from municipal and industrial waste.

- Purification of alternative fuels RDF and compost.

- Purification of cullet, rubber, plastics and other materials coming from recycling.

- Purification of chips, shavings and other shredded wood materials.

- Protection of sugar beet slicers.

Versions of electromagnetic separators

- STE-C type overband electromagnet

Equipped with oil cooling for operation at high temperatures. - STE-DM type overband electromagnet

Forcing by a metal detector - electromagnet power up to 50 kW in intermittent operation. - STE-EX type explosion-proof separator

Manufactured in compliance with the ATEX directive and certified by a notified body.

Overband separator accessories

- Automatic bearing lubricators.

- Belt alignment switches and rotation sensor.

- Winding temperature probe.

- Power supply and control cabinet.

- Supporting structure with adjustable chain slings.

- Discharge chute and self-unloading scrap container.

Working principle of the electromagnetic separator

The electromagnetic separator is usually suspended on a special support structure above the conveyor belt transporting the material. There are two ways to suspend the electromagnetic separator - transversely to the direction of the transported material or longitudinally above the conveyor drive drum. After connecting the power supply to the separator control cabinet, a direct voltage of 110 or 220 VDC is supplied to the electromagnet terminals. The flow of direct current in the winding excites the electromagnet and creates a strong magnetic field that captures metals from the transported material. The captured metals are conveyed by the extractor belt to a discharge chute and then to a scrap container.

Overband electromagnet videos

Why choose our electromagnetic separators?

The electromagnetic separators produced are available in several variants, adapted to the operating conditions and intended use. Our solutions are delivered to users around the world, where they are used in such extreme working conditions as mines, rock grinding plants, cement plants and installations for recycling various types of waste.

To build separators, we use the highest quality materials and components from our European suppliers, which ensures continuity of supply chains and quick order completion times. The electromagnets used in the separators have a winding made of anodized aluminum tape with additional insulation, thanks to which our solutions have the highest insulation class C up to 300°C. This ensures high thermal resistance and long service life of our solutions.

The power supply and control cabinet, adapted to cooperate with the superior control system, is responsible for power supply and control of the separator's operation.

Our technical advisors provide professional advice at the stage of selecting the type of separator, the necessary additional equipment, and participate in the design of the installation of our devices in industrial installations.

Electromagnetic separator price and delivery date

Based on the working conditions specified by the Customer, the appropriate type of separator is selected and its price is determined, which depends primarily on the power of the installed electromagnet. Depending on the ambient temperature and the transported material, electromagnets are offered without cooling (cooling by natural air circulation) or with oil cooling. A more expensive option is an electromagnet cooled by oil due to the different design of the windings and housing. As standard, separators are supplied with NORD drives. The use of SEW drives requires a small additional fee. The color scheme of the device is optional - according to the RAL palette and does not require an additional fee.

The delivery time of the device on request is standardly 6 - 8 weeks. We also fulfill orders with an accelerated deadline. Magnetix also has a large warehouse of separators available immediately.

Magnetix also carries out comprehensive deliveries of electromagnetic separators including the design of the installation, steel structures, control systems and mechanical and electrical assembly. The price of a comprehensive separator delivery with assembly is calculated individually and depends on the complexity of the installation and the scope of work.