Products

Non-ferrous metal separator SWP-26B

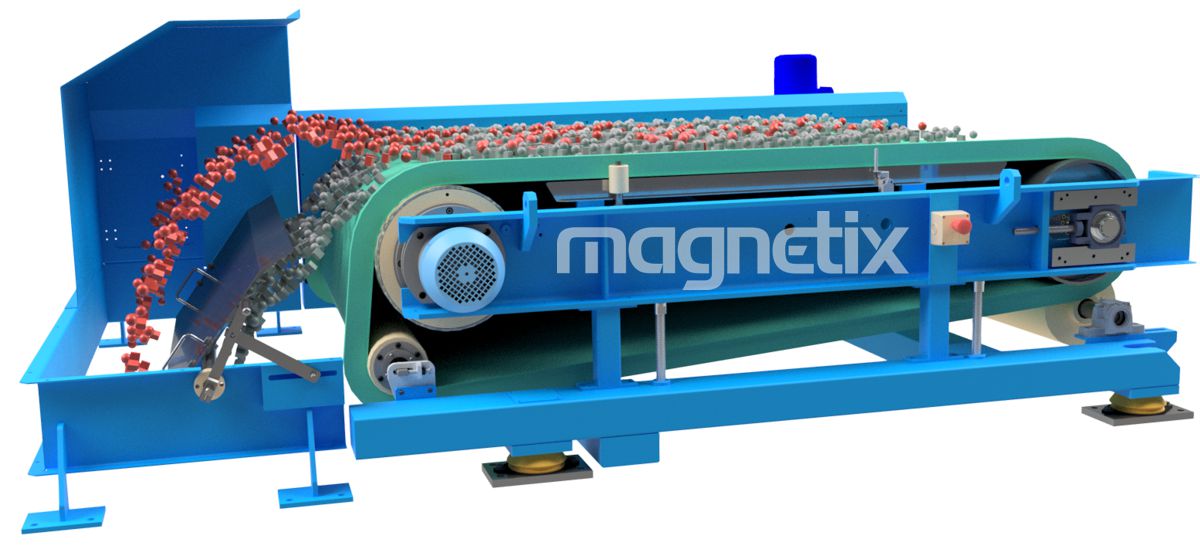

The SWP-26B type eddy current separator is designed for automatic separation of non-ferrous metals from bulk or crushed materials. The SWP-26B separator recovers aluminium, copper, magnesium, zinc, silver and other valuable non-ferrous metals with a grain size above 1 mm with high efficiency. In addition, the separator cleans secondary raw materials such as plastics and glass from non-ferrous metals.

The SWP-26B non-ferrous metal separator is reliable, very robust and designed for continuous operation. The separator is characterized by the highest metal separation efficiency. The powerful neodymium permanent magnets used in the polar wheel have high coercivity, which makes them difficult to demagnetize. This makes the eddy current separator have a long service life.

Features of the SWP-26B metal separator

- Custom made non-ferrous metal separator according to individual requirements.

- Robust and durable design for continuous operation 24/7 under difficult working conditions.

- Working width of the separator up to 1500 mm.

- High-speed magnetic rotor (polar wheel) made of powerful neodymium magnets.

- Speed of the polar wheel up to 4500 RPM due to innovative bearing cooling.

- The frequency of the alternating magnetic field up to 1200 Hz.

- Precise balancing of the polar wheel in class 0.4

- Adjustment of operation parameters with frequency inverters.

- The latest security systems, including electronic rotor braking.

- Reinforced C-type frame enabling quick belt replacement (belt replacement time approx. 30 minutes).

- Corrugated sidewall conveyor belt with increased durability.

- Accessories from leading manufacturers.

Applications of the SWP-26B metal separator

- Separation of non-ferrous metals from alternative fuels RDF.

- Valorization of slags from municipal waste incineration plants.

- Disposal of cars and household appliances.

- Recycling of electronic waste (E-waste).

- Plastic recycling.

- Purification of glass cullet.

- Recovery of metals from mining and processing heaps.

- Purification of wood chips.

Separation of non-ferrous metals

- aluminum

- copper

- brass

- magnesium

- zinc

- tin

- silver

- gold

- lead

Equipment of the SWP-26B metal separator

- 26-pole high-speed magnetic rotor made of high-power neodymium (NdFeB) magnets.

- Epoxy rotor shell reinforced with fibreglass.

- Direct rotor drive by 2-pole NORD electric motor with ROTEX coupling.

- High-speed spherical roller bearings with an innovative cooling system.

- Accelerating conveyor belt.

- Corrugated sidewall conveyor belt made of polyurethane with increased durability.

- Belt drive by NORD geared motor.

- Reinforced C-type separator frame for quick belt replacement.

- Discharge hood with adjustable splitter.

- Rotary brush for belt cleaning.

- Belt guide rollers.

- TELEMECANIQUE belt alignment switches.

- TELEMECANIQUE rotation sensor.

- Control cabinet equipped with SIEMENS PLC.

- NORD frequency inverters for rotor and belt speed adjustment.

- Electronic brake of the magnetic rotor.

- Dustproof separator cover (option).

- Vibrating feeder (option).

Working principle of the non-ferrous metal separator

The operation of the non-ferrous metal separator is based on the principle of magnetic induction. A magnetic rotor rotating at high speed creates a high frequency alternating magnetic field that induces strong eddy currents in metals. Due to the flow of current in non-ferrous metals, a secondary magnetic field is created that opposes the magnetic field of the rotor. The interaction of these fields leads to the creation of the Lorentz repulsive force, which counteracts the force of gravity. The resultant force pushes the metal out of the stream of transported material. The SWP-26B separator is characterized by a high-frequency magnetic field ensuring the highest separation efficiency of very fine metals such as aluminium, copper, magnesium, zinc and silver.