Products

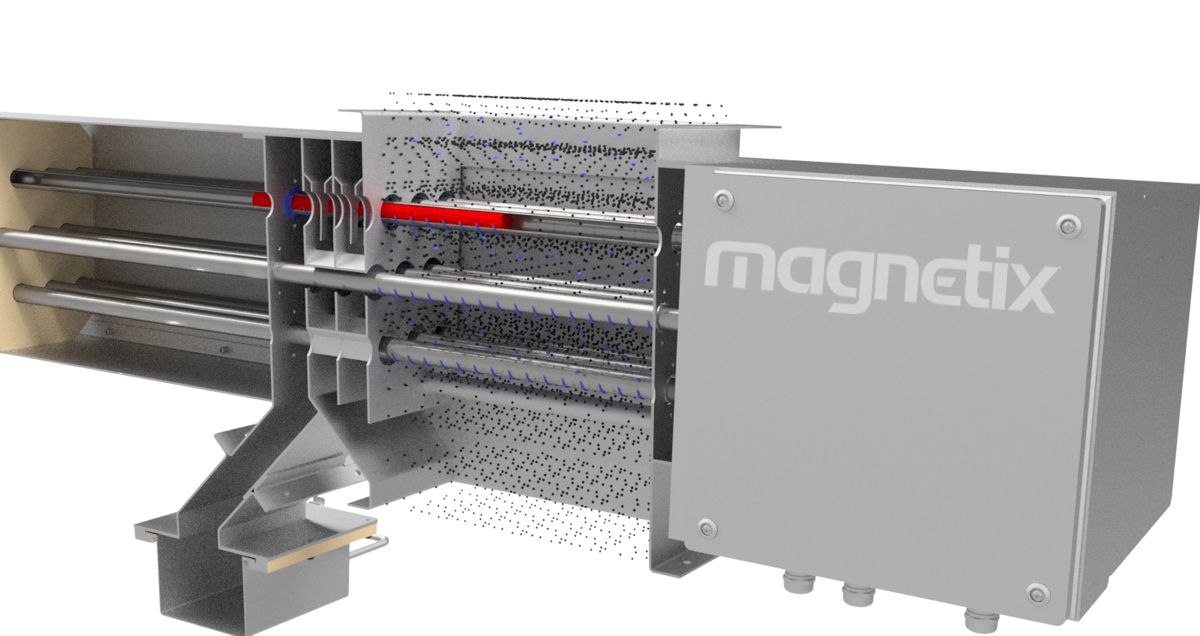

Magnetic grid SMA

The SMA type automated magnetic grid is designed for automatic removal of smallest iron contaminants from fine-grained bulk materials (granulation up to 5 mm) in free-fall systems. The magnetic grid protects process machines against damage caused by metal contamination, prevents production downtime and ensures product quality. The SMA separator also protects the consumer against eating dangerous metal pieces and is a perfect complement to a metal detector.

The SMA self-cleaning grid separator is reliable, very robust and designed for continuous operation. The grid separator consists of neodymium magnetic bars with very high magnetic field intensity and is characterized by the highest metal separation efficiency. The SMA separator enables the separation of filings, iron oxides and even slightly magnetised stainless steel. The powerful neodymium permanent magnets used in magnetic bars have high coercivity, which makes them difficult to demagnetize. Therefore, the grid separator has a long service life.

Features of automated magnetic grids from Magnetix

- Custom made magnetic grid according to individual requirements.

- Robust and durable design ensuring long service life.

- Made with approval for the food industry.

- Certified by the National Institute of Hygiene.

- Separator efficiency above 99%.

- Automatic cleaning from captured metals.

- Simple installation in a gravity chute.

- Inlet max. 600×500 mm.

- Magnetic bars made of powerful neodymium magnets.

- Magnetic flux density reaching 12 000 Gauss on magnetic bars.

- High coercive magnetic material.

- Dustproof grid housing made of high-quality stainless steel.

- Working temperature up to 300°C (using samarium-cobalt magnets).

- Optional explosion-proof design in accordance with the requirements of the ATEX directive.

Applications of self-cleaning grid separators

- Removal of metal contaminants with the highest efficiency from sugar, salt, flour, coffee, powdered milk, spices and other bulk food products with granulation up to 5 mm.

- Separation of metals from grain, feed and feed additives.

- Purification of wood chips, shavings, sawdust and wood dust.

- Purification of grit, sand and flour.

- Purification of plastic granulates.

Versions of magnetic grids

- SMA-2R type magnetic separator with 2 rows of magnetic rods

- SMA-3R type magnetic separator with 3 rows of magnetic rods

- SMA-4R type magnetic separator with 4 rows of magnetic rods

- SMA-EX type explosion-proof separator manufactured in compliance with the ATEX directive and certified by a notified body.

As standard, separators are manufactured with magnetic rods made of high-energy neodymium NdFeB magnets with an operating temperature of up to 80°C. Optionally, the magnetic rods can be made of high-temperature neodymium magnets of the SH class with an operating temperature of up to 150°C or samarium-cobalt SmCo with an operating temperature of up to 300°C.

Working principle of the automated magnetic grid

The contaminated product passes through the separator inlet and flows through a multi-row system of magnetic bars. Iron particles are attracted by the magnets and collected under the cover tubes, while the purified product falls freely and leaves the separator through the outlet. During the cleaning phase, the magnets located in the cover tubes are blown into the cleaning chamber with compressed air. The captured iron particles are moved behind the magnets to the splitter, where they fall into the chute for contaminants.

The cleaning of the separator is carried out sequentially. The magnets rows are sliding out one after another in the set intervals by the PLC relay controlling operation of the solenoid valves.

Why choose our magnetic grids?

Grids magnets must meet the highest quality standards required for food and chemical installations. The quality of Magnetix products is confirmed by the certificate of the National Institute of Public Health (PZH).

Class N54 neodymium magnets with an innovative nano coating were used to produce magnetic grids, protecting them against damage and corrosion. The highest quality industrial automation and pneumatics were also used - SIEMENS control and measurement equipment, CKD solenoid valves, HAFNER air preparation stations, RITTAL housings. The grids bodies are made of thick-walled stainless or acid-resistant steel using laser welding technology, ensuring high-quality welds without overheating the material.

In addition to the standard catalog offer, we also produce grate magnets to individual orders, according to the detailed guidelines of the Customer and local conditions.

Magnetic grid price and delivery time

The price of a magnetic grid depends primarily on the number of magnetic bars used in it and the magnetic material from which they are made. Magnetic bars made of high-temperature neodymium magnets are expensive. Samarium-cobalt magnets are even more expensive due to the valuable cobalt.

Magnetix also carries out comprehensive deliveries of magnetic separators including the design of the installation, steel structures, control systems and mechanical and electrical assembly. The price of a comprehensive delivery of a separator with assembly is calculated individually and depends on the complexity of the installation and the scope of work.

The delivery time of the device on order is usually 6 - 8 weeks. We also carry out orders with an accelerated deadline. Magnetix also has a large warehouse of separators available immediately.