Products

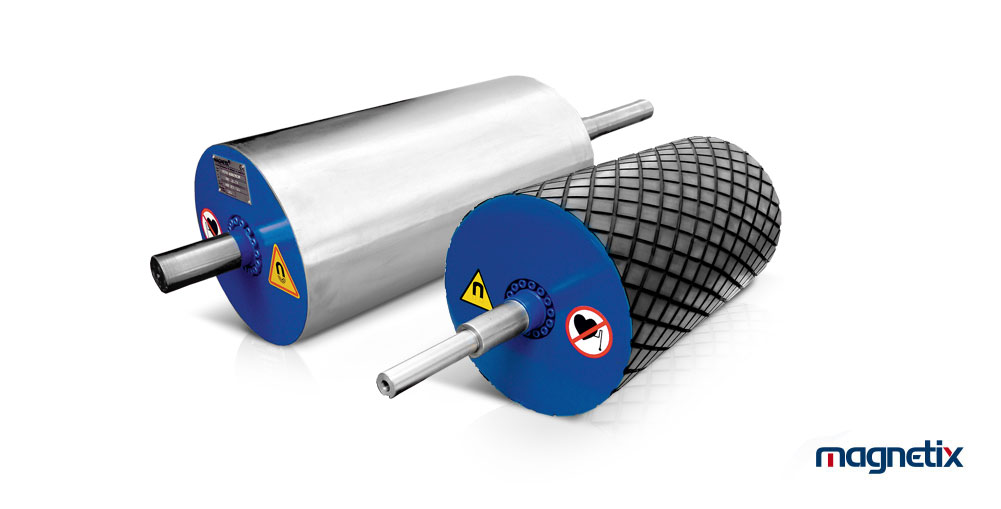

Magnetic pulley BM

The BM type magnetic head pulley is designed to be built into a belt conveyor instead of the drive drum and is used to separate ferrous metals from bulk materials transported on the belt. The magnetic pulley protects mills, crushers and other process machines against damage caused by tramp metal and is a perfect complement to the over-belt separator. The BM pulley is also used to recover valuable ferrous scrap in waste recycling processes.

The BM magnetic pulley is reliable, very robust and designed for continuous operation. The BM pulley is characterized by high metal separation efficiency. The ferrite or neodymium permanent magnets used in the pulley have high coercivity, which makes them difficult to demagnetize. Therefore, the magnetic pulley has a long service life.

Features of magnetic pulleys from Magnetix

- Custom made magnetic pulley according to individual requirements.

- Can be adapted to all types of belt conveyors.

- Robust and durable design ensuring long service life.

- Magnetic pulley diameter up to 800 mm.

- Working width of the magnetic pulley up to 2000 mm.

- Magnetic circuit with high magnetic field intensity.

- High coercive magnetic material.

- Pulley shell made of austenitic stainless steel.

- Increased durability of the pulley shaft.

- Clamping sets for quick shaft replacement.

- Anti-slip lining - rubber coating or checker plate.

- Operating temperature up to 150°C.

Applications of magnetic head pulleys

- Additional stage of separation of ferrous metals behind the overband magnet.

- Removal of metal contaminants at particular stages of cement production.

- Purification of grit, sand, flour and other mineral materials.

- Recovery of iron scrap from mining and processing heaps.

- Separation of tramp iron from moulding sand.

- Recovery of ferrous scrap from municipal and industrial waste.

- Purification of alternative fuels RDF and compost.

- Purification of cullet, rubber, plastics and other materials coming from recycling.

- Purification of chips, shavings and other shredded wood materials.

- Stainless steel separation.

Versions of magnetic pulleys

- BM-F type ferrite pulley

Made of ferrite magnets with medium magnetic field intensity;

Designed to remove larger metal contaminants from the transported material, such as screws, bolts and other broken machine parts. - BM-N type neodymium pulley

Made of strong neodymium magnets with high flux density;

Designed to remove small metal contaminants from the transported material, such as bearing balls, metal filings, iron oxides and others with a small adhesion surface to the magnet and weakly magnetically susceptible. - BME type electromagnetic pulley

Consisting of a DC electromagnet with a high range magnetic field;

Intended for separating large-sized iron scrap.

The magnetic pulleys we produce are rubberized at the customer's request. We use rubber linings with a "diamond" profile, 6 or 8 mm thick. Due to the possibility of damage to the magnets during vulcanization in the autoclave, the drums are rubberized using the "cold" method using specialized adhesives.

The magnetic pulley can be additionally equipped with spherical roller bearings in dust-proof housings and a cylindrical-bevel gear motor.

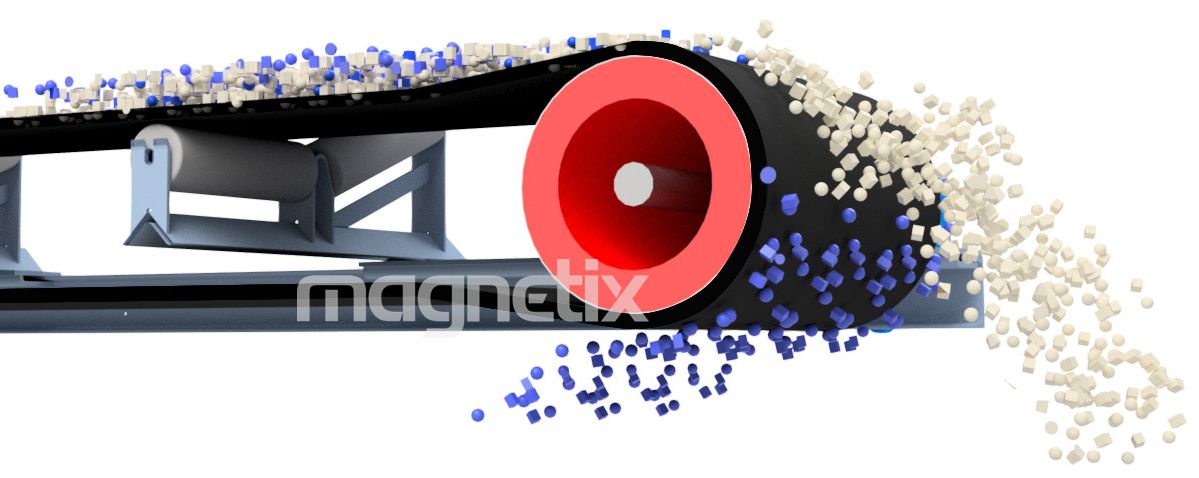

Working principle of the magnetic pulley

The material to be separated is transported on a belt conveyor. As the material passes through the head pulley, it is exposed to a magnetic field generated by strong permanent magnets installed in the pulley body. Ferrous metals are captured by the magnetic field and held on the conveyor belt, while the magnetically neutral material falls freely from the conveyor. Metals fall off the belt at the point where the belt no longer adheres to the pulley, either under the influence of gravity or with the help of cleats located on the belt. The efficiency of separation is enhanced by an adjustable splitter placed under the belt conveyor.

Why choose our magnetic pulleys?

Magnetic pulleys from Magnetix are manufactured in many versions for customers all over the world. Pulleys are available in diameters from 100 to 1200 mm and working widths up to 3000 mm using ferrite and neodymium magnets.

An innovative technology of water jet cutting of magnets and yokes has been developed for the production of magnetic systems, thanks to which very high precision of magnet assembly has been achieved, and consequently high power of the emitted magnetic field.

Magnetix ensures an individual approach to each order and a quick completion date, also for serial deliveries for regular customers.

Magnetic pulley price and delivery time

The price of a magnetic pulley depends primarily on the diameter, working width and magnetic material used. Pulleys made of neodymium magnets are more expensive due to the constantly rising prices of rare earth metals. Bearings and drive are selected individually depending on the parameters of the belt conveyor.

The delivery time of the device on order is usually 4 - 6 weeks. We also fulfill orders with an accelerated deadline. Magnetix also has a large warehouse of separators available immediately.